Precision Structures & Optics

Clarity. Accuracy. Reliability.

For more than 50 years, General Dynamics has designed and manufactured custom precision metal optical components for defense, space and airborne applications. We provide end-to-end design, fabrication and testing of beryllium and aluminum optics that have gone into some of the world’s most advanced optical systems that support critical airborne and space-based targeting, surveillance and observation missions.

Recent Programs

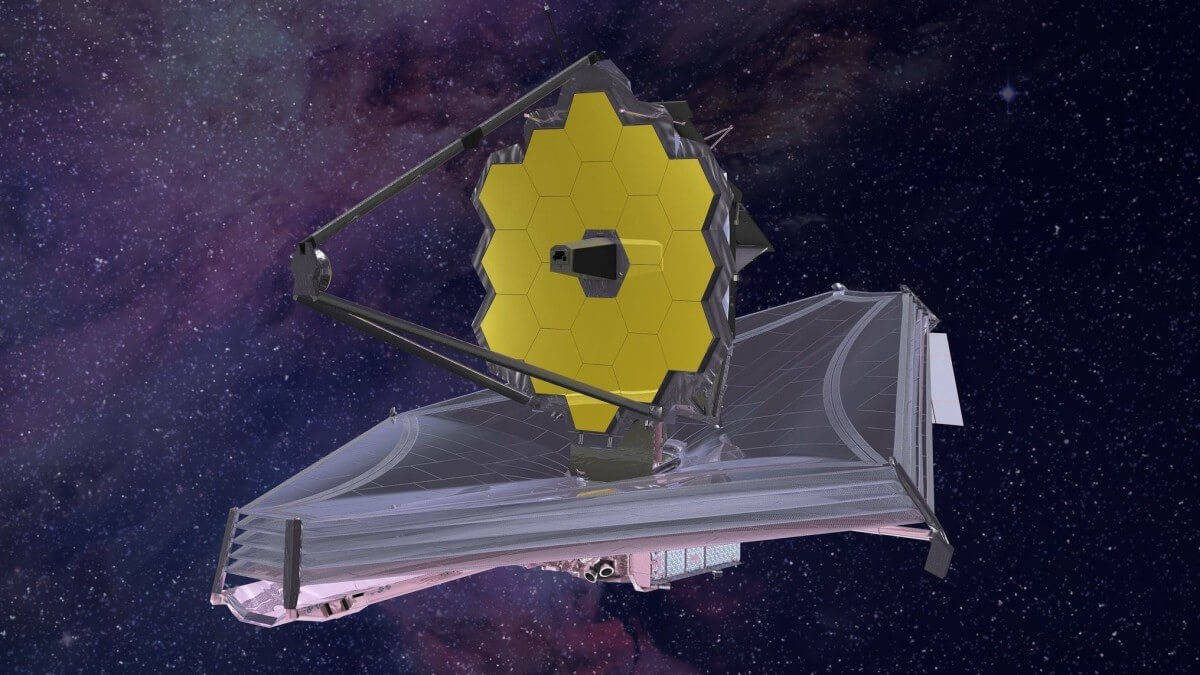

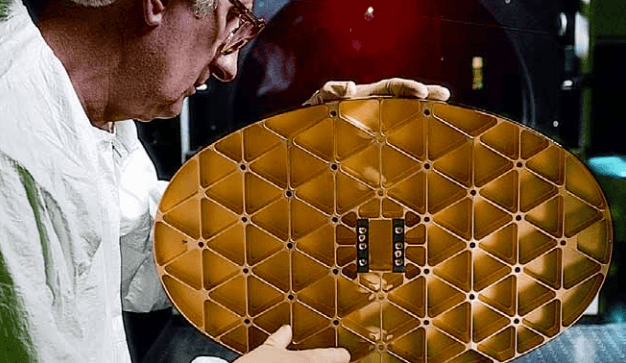

James Webb Space Telescope

Since 1998, the General Dynamics team in Cullman, Alabama has built 21 primary mirror segments, two secondary mirrors, 21 delta frames, 10 various aft optical components and beryllium panels for the James Webb Space Telescope.

SM-3 Interceptor

General Dynamics announced that it has been selected by Raytheon Missiles and Defense to provide advanced optical components and structures for the Standard Missile-3 (SM-3) Block IB and SM-3 Block IIA interceptors with two firm-fixed price contracts.

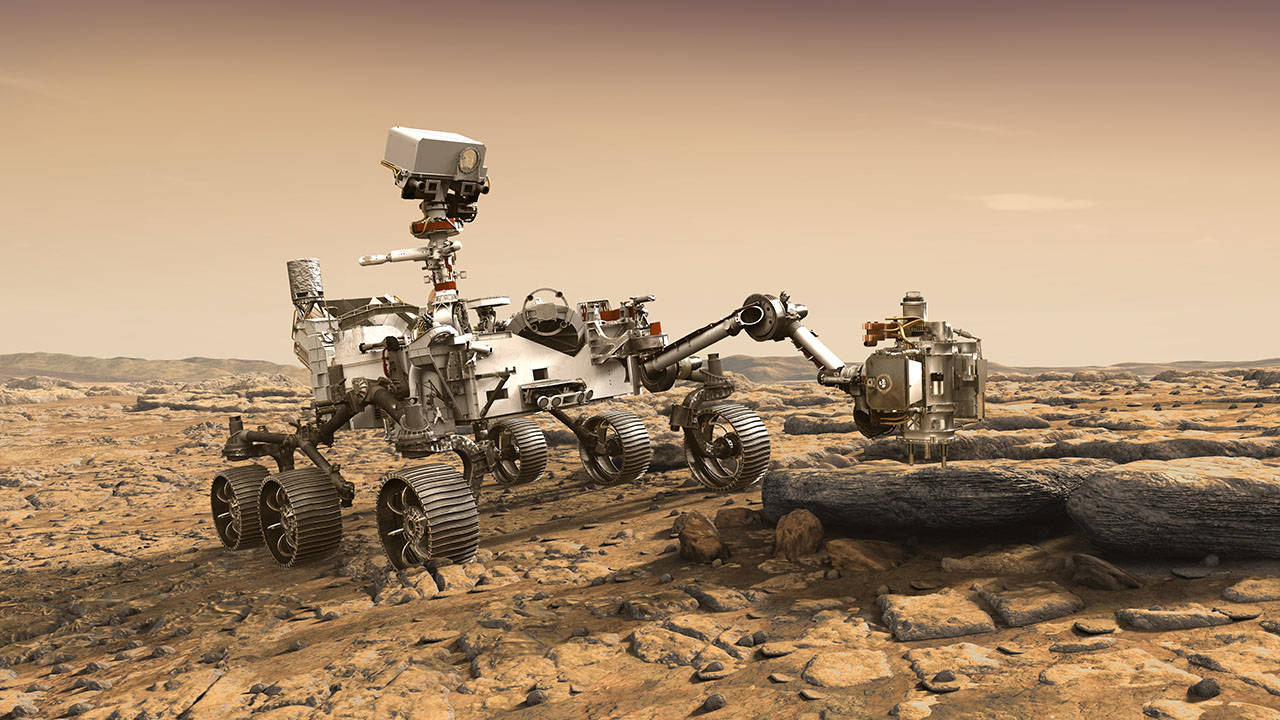

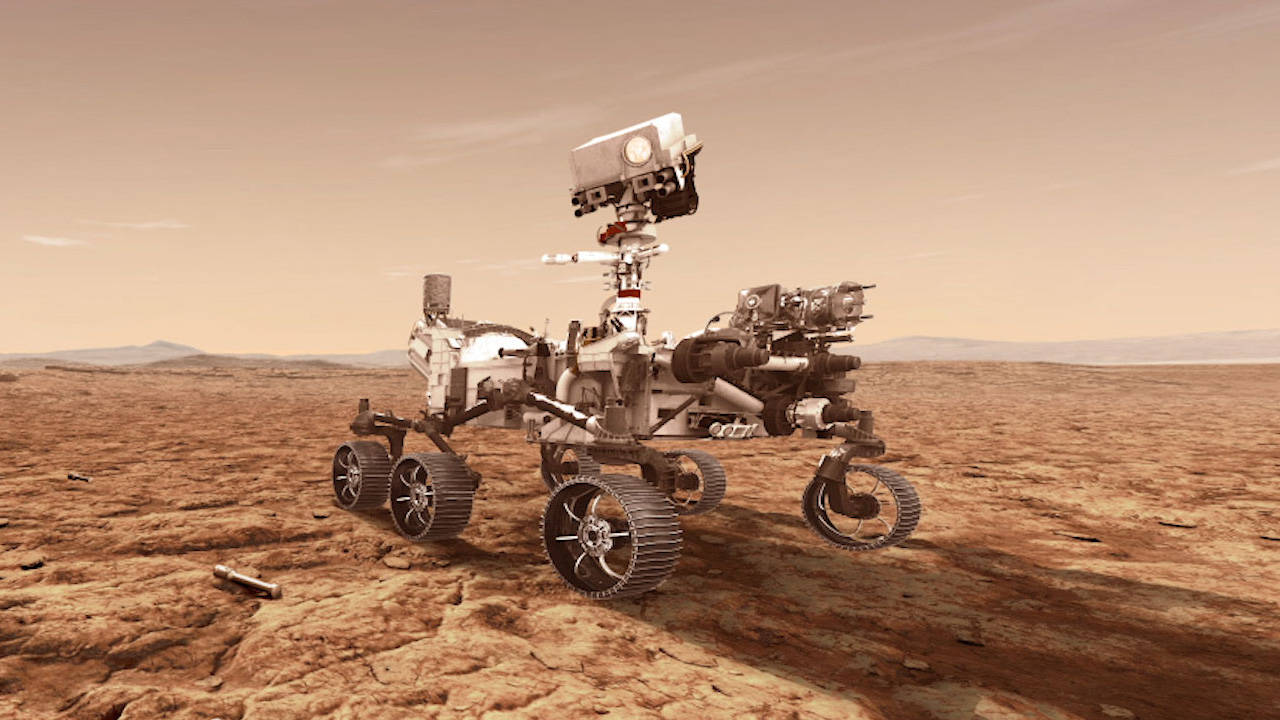

Mars 2020 Rover

The Mars 2020 rover’s wheels and suspension are supported by custom beryllium components that were manufactured at General Dynamics' Cullman, AL facility. Beryllium is extremely strong and lightweight, making it ideal for the harsh environment of the Red Planet.

Our Capabilities

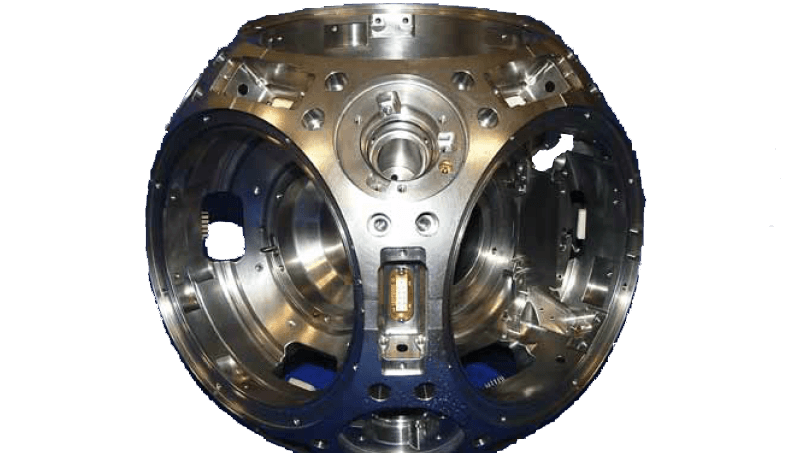

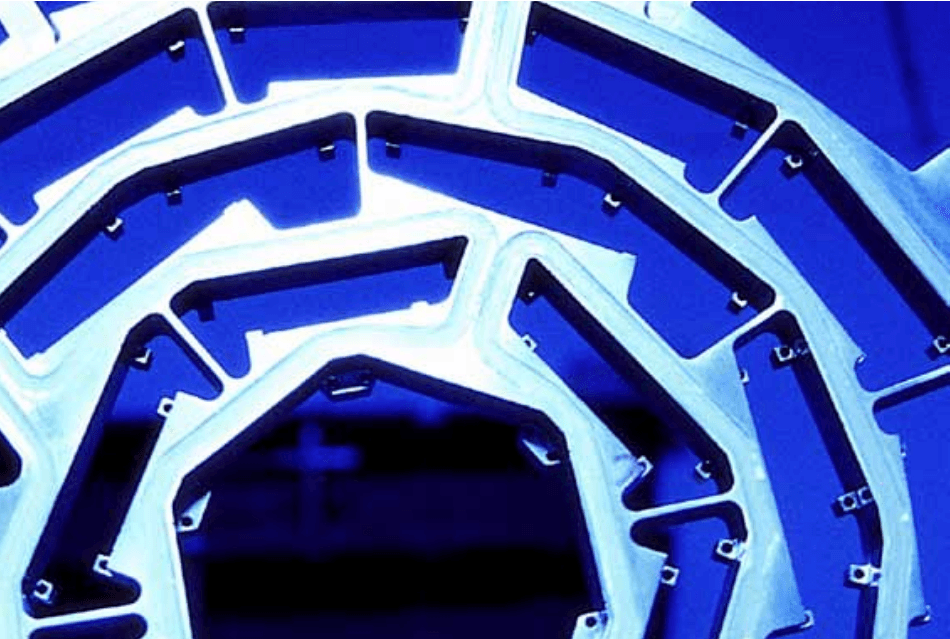

Beryllium Machining

We provide close tolerance machining and processing of beryllium and its alloys to deliver optics and optical assemblies with precise, complex geometric features. With over 50 years of experience and state-of-the art equipment we can achieve virtually unmatched tolerances. One-third the weight of aluminum, six times stiffer than steel and with a high thermal stability, beryllium is the ideal material for applications in space or other harsh environments. We machine our beryllium to tolerances up to 1/100,000 of an inch (0.000001 in.) to meet the most demanding mission requirements. Applications include:

- Precision metal optics and assemblies

- Telescopes with diameters ranging from 3” to 5’ to support critical airborne and space-borne targeting, surveillance and observation

- Flat, aspheric or spherical mirrors (nickel plated, polished, heat treated and anodized)

- Gimbals

- Black bodies

- Scan Mechanisms

- Collimators

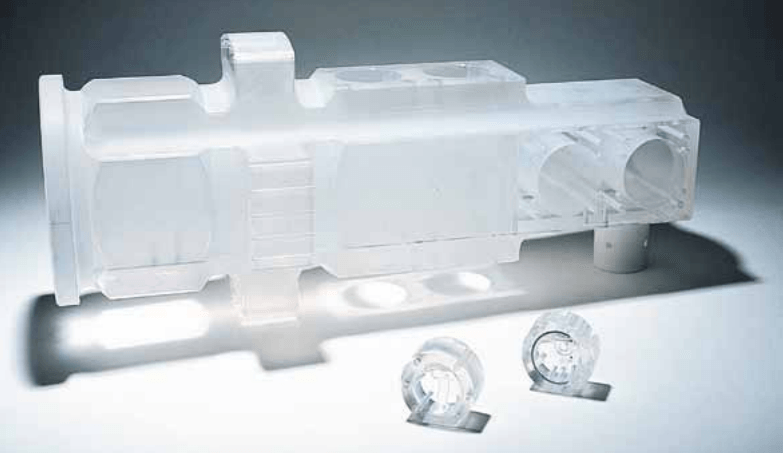

Milling

We provide milling capabilities to produce precise, light-weight structures from high performance materials including Beryllium and its alloys, Titanium, Aluminum, Quartz, machineable glass, Inconel, Magnesium and other exotic and conventional materials. Applications for our milling capabilities include:

- Satellite Components

- Inertial Navigation Components

- Optical Benches

- Infrared Seekers

- Nuclear Reactors

- Strategic and Tactical Weapons

Turning

We provide precision capabilities to generate complicated part geometries from high-performance materials including Beryllium and its alloys, Titanium, Aluminum, Inconel, stainless steel forgings and other exotic and conventional materials. Possible applications include:

- Satellite Components

- Inertial Navigation Components

- Mirror Substrates

- Nuclear Reactors

- Strategic Missiles

- Momentum/Reaction Wheels

- Commercial Scanners

Electrical Discharge Machining (EDM)

We provide precision electrical discharge machining (EDM) of high-performance materials including Beryllium and its alloys, Titanium, Aluminum, stainless steel and other thermally conductive materials. Possible applications include:

- Material Extraction

- Gas/Air Bearings

- Heatsinks (Satellites & Aircraft)

- Optics & Optical Benches

- Infrared Seeker Components

- Satellite Sensors

Lapping & Grinding

General Dynamics provides lapping and grinding capabilities for high performance materials including Beryllium and its alloys, Titanium, Aluminum, Quartz, Sapphire, machineable glass and ceramics. Possible applications include:

- Inertial Navigation Systems

- Momentum/Reaction Wheels

- Rotary and Linear Air Bearings

- Optics

- Scientific Experiments

- Space Instrumentation

Precision Metal Optics

We design and manufacture custom precision metal optical components and optical assemblies for commercial, defense and space-based applications. We provide end-to-end design, fabrication and testing of beryllium and aluminum optics ranging from single- and multi-faceted scan mirrors to plano and aspheric mirrors to complex telescope assemblies.

Contact Us

For more information about our beryllium machining solutions, you may contact us.

Phone: 256-737-5200

Fax: 256-739-8298

General Dynamics Mission Systems

6717 Alabama Highway 157

Cullman, AL 35057

We are also equipped to machine other exotic and conventional materials, including titanium, aluminum, quartz and glass. Download our datasheet for a complete listing of our Precision Machining In-House Capabilities.